Integrating Massive Dimension’s Pellet Extruder with Kuka Robot

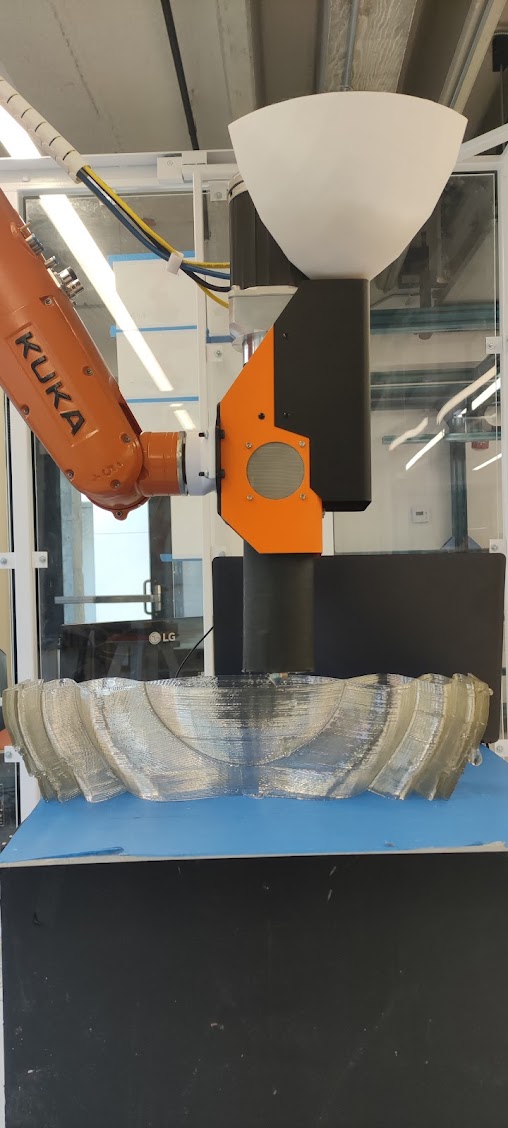

In this project, we explore interactive approaches in robotic fabrication by integrating Massive Dimension’s pellet extruder with a Kuka robot. The integration employs an IoT approach through a UDP connection, allowing seamless communication between the extruder and the robot. This method significantly broadens the scope of experimentation in 3D printing, providing more flexibility and control over the printing process.

I developed a customized OSC (Open Sound Control) interface, along with ESP32 firmware and toolpath integration, to enhance robot control. This allows for precise synchronization between the robot and the pellet extruder, enabling real-time adjustments during fabrication.

One of the key advancements in this project is the creation of customizable user interfaces for controlling the pellet extruder. Using OSC, the extruder can connect with various software platforms like Grasshopper, Blender, and TouchOSC, offering a range of interactive options for adjusting and managing the extruder in real time.

Robotic 3D Printing with IoT Integration

The IoT-driven integration allows for innovative control mechanisms, expanding the potential for complex and customized 3D prints. By using UDP connections and OSC, the system supports a more dynamic interaction between the robot and extruder, making adjustments easier and improving overall printing precision.

Expanding Capabilities in Robotic Fabrication

This project enhances our lab’s capabilities in robotic 3D printing, opening up new possibilities for experimentation in robotic fabrication. The seamless integration of a pellet extruder with a robotic arm not only improves manufacturing processes but also offers a scalable solution for more efficient and customizable production.

Future Possibilities

Our exploration into the integration of IoT with robotics paves the way for future advancements in digital fabrication. With the potential to connect different software platforms and customize user interfaces, the possibilities for innovation in robotic 3D printing are endless.